|

Leather furniture is like a work of art. With our

custom made line of sofas, chairs, and ottomans, you can select the style,

color and configuration that best suits your personality.

Our all-over leather furniture is covered with 100% top

grain Argentine leather, recognized as one of the top quality furniture

leathers in the world. We do not use vinyl or split grain leathers in

manufacturing any of our products. We start with a kiln-dried hardwood

frame for lasting endurance (it's guaranteed for life!). Then we

custom cut & match our high density foam pillows to ensure even comfort

wear and durability.

We are frequently asked, "won't that take a long

time?". We have stream lined the ordering, production and

delivery process so that we deliver custom made sofas in 3 to 4 weeks.

Why is "Top Grain" so important? Read on

below about the tanning process to understand why having 100% top grain is

essential if you want lasting furniture that will hold up to use, age well, and hold it's beauty. We are confident that the

more you know about fine leather, the more you will want to order your next

leather from TruloveStyle.

The Tanning Process

|

|

1. Liming

A tannery does not know what kind of hide they have purchased until

the hair has been removed. The process of removing the hair is

called liming. Liming is accomplished by placing the hides in large

narrow drums, shaped like a wheel. The drums rotate for many hours

until all of the hair is removed.

|

|

|

2. Selection and Sorting

The hides are then sorted as to their quality. The highest quality

hides are those with the fewest markings. The least amount of work

must be done to these hides to prepare them for finishing.

|

|

3. Tanning

This process preserves the hide and makes its natural

characteristics permanent. Tanning is accomplished by placing the

hides into large rotating drums for 24 hours. These drums contain

alkaline chrome salts. The hides emerge with a slight bluish tone.

This state is called the "Wet Blue" state. This process

enables current day leather to be softer and not to crack or peal.

|

|

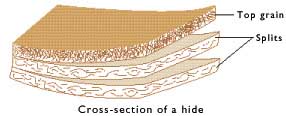

4. Splitting

The average thickness of a cowhide is 5mm. Upholstery leather

requires a minimum thickness of .9-1.1mm. The hides are split in a

splitting machine. This operation divides the hide in at least two

hides: the grained hide and one or two splits.

|

|

The strength of the fibers will vary with

these hides. The fibers are very strong on the grained hide, and get

weaker the deeper the split. The split has much less resistance and

flexibility than the grained hide. These splits are processed as

suede or embossed with graining to make it look like the grained

hide. This is done to offer a lower price on some leather furniture.

5. Finishing

A. Aniline Color: At the beginning of the

finishing process, hides are placed into the wheel shaped drums to

soften, remove excess water and apply an aniline dye. This means

that they are dyed with color all the way through. The aniline dye

penetrates completely through the entire hide. At this stage the

hides are "pure top grain aniline". These superior hides

(free from flaws) are then tumbled in drums for several hours to

give added softness. This is called milling. These hides are now

done. All other hides progress through additional surface

treatments.

B. Scar Correction - Buffing: Heavily scarred

hides must receive correction. This correction is done by feeding

them through a machine that is calibrated to the pressure needed to

smooth out the hide. The graining is, therefore, lost in the

process. These hides must later be embossed with

"graining".

C. Base Coat (Color): Hides then go through the

process of receiving a consistent color over the entire surface.

This color is close to the aniline color already received. This

enables a less apparent color contrast, if the hide somehow gets

ripped. At this point, the hide is considered protected, aniline

dyed with a base coat of color. These leathers are uniform in color

with the natural markings being covered.

D. Top Coat (Clear): These hides then go

through a clear coat finish. This seals the base color to the hide.

The color will now not rub off or be damaged.

E. Embossing: Because these hides were buffed

smooth, the next process is embossing a grain into it. This is

accomplished through heat and pressure. A hot plate is used which

has the grain pattern etched into it. Lesser quality hides receive

more buffing and embossing. With more embossing, the hide becomes

firmer and less soft to the touch. |

|

| | TruloveStyle offers home furnishings and accessories from around the world that are unique, interesting, and beautiful. Our eclectic collection includes aged reproduction furniture, antiques, original arts and crafts, mirrors, lamps, floral designs, glassware, seating, tables, curios, armoires and custom leather.

Visit our showroom Mon-Sat 9 am - 6 pm

7150 Hwy 72

Cherokee, Alabama

(1 Mile East of The Natchez Trace)

We deliver/ship anywhere!

| | |

|

| Copyright 2001-2003 TruloveStyle. All rights reserved. Web Development by TimberLion Marketing www.timberlion.com |

|